Holland Scaffold Supply | HSS | Products

Holland Scaffold Supply supplies scaffolding products worldwide to traders, local distributors, onshore & offshore projects, industrial projects, gas and oil projects and more. Contact us today to discuss your requirements.

Scaffolding tubes and more

Holland Scaffold Supply supplies both aluminum and galvanized steel tubes for scaffolding and fall protection systems. All tubes have an outer diameter of Ø48.3 mm (1.9 inches) and wall thicknesses of 3.2 mm, 3.7 mm (schedule 40) or 4.0 mm, depending on the project specifications. Other diameters and wall thicknesses are available on request.

Aluminum tubes are manufactured from EN-AW 6061 T6, 6060 T66 or 6082 T6 alloys, which are known for their excellent strength-to-weight ratio, corrosion resistance and light weight, with a tensile strength of 260–310 MPa and a yield strength of 240 MPa. Steel tubes are produced from high-strength structural steel S235GT Type 4, a low-alloy material with a tensile strength of more than 400 MPa and a yield strength of 235 MPa. The steel tubes are hot-dip galvanized (60 microns) for long-term corrosion protection. Each tube and coupler is 100% traceable by lot number and comes with a material test certificate in accordance with EN 10204-3.1.

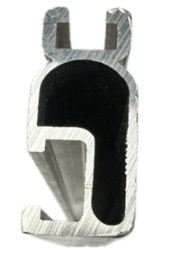

Scaffolding couplers

Holland Scaffold Supply's right angle and swivel wedge couplers are designed for precision, durability, and consistent performance. Each coupler consists of components made of carefully selected materials:

- Body and wedges – manufactured from EN S355MC (1.0976), a thermomechanically hot-rolled fine-grained structural steel with a minimum yield strength of 355 MPa, designed for cold forming operations such as bending and folding. This material provides superior strength, formability and impact resistance for demanding scaffolding structures.

- Wire – manufactured from EN S235JRC+C (1.0122) cold-drawn bars, providing improved dimensional accuracy, a glossy surface and a uniform microstructure. Its excellent weldability and bending performance (180° flat bending without cracking) make it ideal for the production of couplers.

Each coupler is hot-dip galvanized according to NEN-EN-ISO 1461:2009, which provides long-term protection against corrosion. This ensures that our couplers maintain their integrity and strength even under harsh environmental conditions.

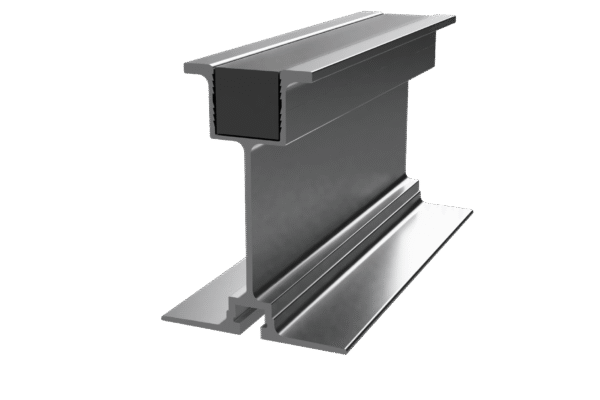

Other extrusions/profiles

Holland Scaffold Supply delivers custom-made aluminum extrusions and profiles for a wide range of industrial and structural applications. From concept to completion, we support customers across various industries including construction, offshore and engineering with precision-engineered profiles tailored to their specific requirements.

Our in-house design team provides full support in concept development, design, and technical drawing, ensuring that every profile meets functional and dimensional requirements. We assist in alloy selection, taking into account mechanical properties, corrosion resistance and intended application. And we coordinate die production for both standard and complex geometries.

Profiles can be supplied in a wide variety of alloys and tempers, including EN-AW 6060 T66, 6061 T6, and 6082 T6, offering an optimal balance between strength, formability and surface finish. Post-extrusion processes such as anodizing, powder coating, and precision cutting to size are available upon request, providing a ready-to-install solution tailored to your project.

All profiles are produced under strict quality control, with full traceability and certification in accordance with EN 10204-3.1. Whether you require lightweight structural members, bespoke components, or large-scale industrial extrusions, Holland Scaffold Supply ensures consistent quality, reliable delivery, and complete technical support from start to finish.

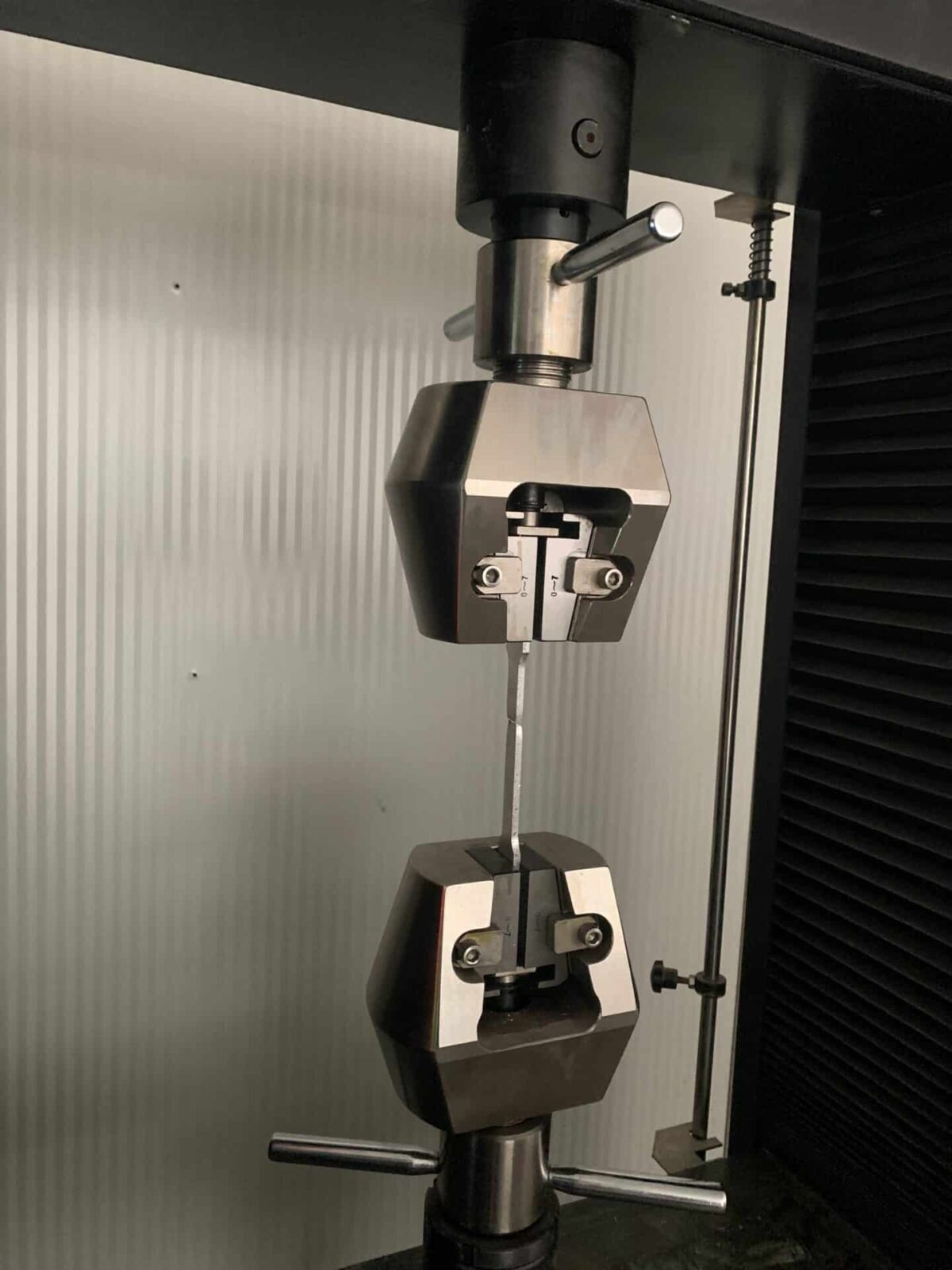

Material testing and advice

All materials supplied by Holland Scaffold Supply are subjected to rigorous mechanical and chemical testing, performed in accordance with relevant EN and ISO standards. Typical examinations include tensile strength, yield strength, elongation, hardness and chemical composition analysis.

Each batch is fully traceable and accompanied by a Material Test Certificate (MTC) EN 10204-3.1, ensuring transparency and compliance throughout the supply chain. Our quality engineers review and verify every test result to confirm conformance with customer and project-specific requirements.

Beyond testing, our consulting services provide expert support in material selection, alloy optimization and performance evaluation for demanding applications. Whether you are developing a new product, assessing structural performance, or optimizing for weight reduction and corrosion resistance, our specialists can advise on the most suitable alloys, coatings, and treatments to meet your objectives.

At Holland Scaffold Supply, we combine technical expertise with a practical understanding of real-world project demands, ensuring that every solution we deliver is safe, certified and fit for purpose.

ISO - 9001

Holland Scaffold Supply operates under a certified ISO 9001 Quality Management System, ensuring consistent quality, traceability, and continuous improvement across all operations. This certification demonstrates our commitment to meeting customer requirements and maintaining the highest standards in product reliability, documentation and service. Through systematic quality control and regular audits, we guarantee that every product and process aligns with international best practices for safety, efficiency, and customer satisfaction.